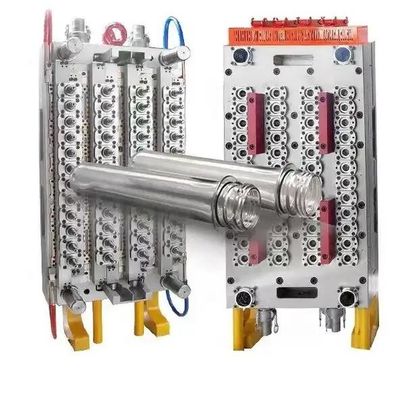

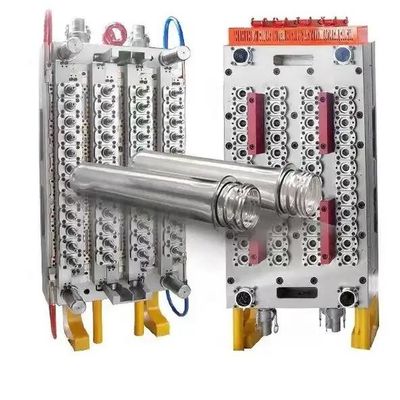

Custom PET Preform Mold Components | Precision Tooling for Injection Molding

Product Overview

Custom PET plastic preform injection mold parts are precision components used in preform moulds for high-output injection molding of PET and engineering plastics. Senlan Precision manufactures mold components strictly according to customer drawings, supporting materials including ABS, PP, PC, PA66, PVC, with stable dimensional accuracy and repeatability for multi-cavity preform mould applications.

Key Features & Advantages

-

Custom mold parts for PET preform injection mould systems

-

Compatible with ABS / PP / PC / PA66 / PVC processing requirements

-

High dimensional accuracy for multi-cavity preform moulds

-

Stable performance under continuous high-cycle production

-

Precision machining for core, cavity, neck ring, and structural parts

-

Consistent part interchangeability for maintenance and replacement

-

Built-to-Print OEM manufacturing based on customer specifications

Applications / Industry Use

-

PET bottle preform injection moulds

-

Beverage and liquid packaging mould systems

-

Plastic bottle and container preform tooling

-

Multi-cavity injection moulds for packaging production

-

Engineering plastic mould assemblies

Mold Structure & Design Description

PET preform injection mold parts are typically integrated into high-cavity mould structures where alignment accuracy, thermal stability, and wear resistance are critical. Components are manufactured to ensure precise fit between core, cavity, and neck ring systems, supporting uniform preform wall thickness, stable gate formation, and consistent molding performance across all cavities.

Manufacturing Capability & CNC Machining

Senlan Precision produces PET preform mold parts using advanced CNC machining and precision finishing processes to meet tight tolerance and surface requirements.

Manufacturing capabilities include:

-

CNC turning and milling for mold cores, cavities, and inserts

-

Precision grinding for alignment and concentricity control

-

EDM and wire-cut EDM for complex internal geometries

-

Multi-cavity dimensional consistency control

-

Machining suitable for PET and engineering plastic mould standards

High-precision machining is supported by equipment from MAKINO and HARDINGE, ensuring stable accuracy and repeatability.

Custom Development / OEM Cooperation Process

-

Customer submits 2D drawings or 3D CAD files

-

Engineering review of structure, tolerance, and material

-

CNC machining and EDM processing

-

In-process dimensional inspection

-

Final quality verification

-

Export packing and delivery

All projects follow a Built-to-Print / OEM manufacturing model.

Quality Control & Export Experience

-

Incoming material inspection

-

In-process dimensional and structural checks

-

Final inspection before shipment

-

Batch consistency control for multi-cavity mould parts

-

Long-term cooperation experience with overseas mould manufacturers

Related Products

-

PET preform mold core and cavity components

-

Neck ring and gate system mold parts

-

Multi-cavity injection mold inserts

-

Precision mold alignment and guide components

-

Custom CNC machined mold tooling parts

FAQ – Technical & Purchasing

Q1: Are these mold parts only for PET materials?

No. Parts can be manufactured for PET as well as ABS, PP, PC, PA66, and PVC moulding applications.

Q2: Can these parts be used in high-cavity preform moulds?

Yes. They are designed for dimensional consistency in multi-cavity mould systems.

Q3: Do you provide standard parts or only custom parts?

All parts are custom-made according to customer drawings and specifications.

Q4: What information is required for quotation?

Technical drawings, material requirements, tolerance specifications, cavity quantity, and order volume.

Request a Quote

Please provide your drawings and technical requirements to receive a professional quotation for custom PET plastic preform injection mold parts.

Our engineering team supports precision manufacturing for stable, high-output injection mould systems.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!