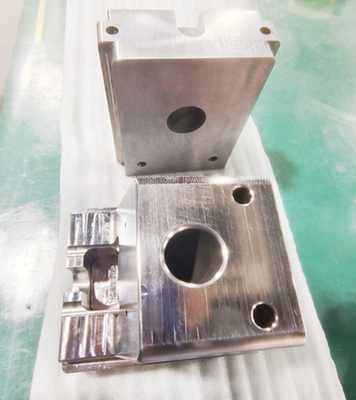

Slider Mold Parts Fittings For EDM Of P20 Material

Slide mold parts mechanisms are engineered systems comprising key components including forming surfaces, slider bodies, guide pins, wedges, press blocks, and wear plates. These precision components undergo surface nitriding treatment to minimize wear and extend service life during injection molding operations. The advanced design enables production of complex geometries while maintaining structural integrity against displacement forces generated by injection pressure.

Slider Mold Parts Specifications

| Material |

P20 |

| Hardness |

48-52HRC |

| Heat treatment |

Available |

| Service |

Made-to-order |

| Surface treatment |

/ |

| Closest tolerance |

±0.01mm |

| Polishness |

Ra0.6 |

| Axiality |

0.01mm |

| Verticality |

0.01mm |

Our Manufacturing Services

- Customer-focused solutions tailored to your requirements

- Rapid sample delivery and production according to your BOM

- Professional production team with strict quality control

- Comprehensive one-stop solutions for long-term partners

- Custom sizing and OEM/ODM services available

- 100% pre-shipment inspection with quality warranty

- Competitive pricing with excellent service and flexible terms

Product Range

- Core pins, cavity pins, insert pins

- HSS punches, precision punches, special-shaped punches

- Ejector pins, ejector sleeves, two-stage ejector pins

- Guide pillars, guide bushings, guide post sets

- Slide core units, latch locks, locating series

Quality Assurance Process

SENLAN maintains rigorous quality control throughout the manufacturing process, from raw material inspection to finished product verification. Our mold parts guarantee high precision, superior surface finish, and extended service life.

Comprehensive Inspection Stages

- Material incoming: 100% inspection

- Rough finished: 100% inspection

- Heat treatment: random inspection

- Face grinding: 100% inspection

- Center-less cylindrical grinding: 100% inspection

- OD/ID grinding: 100% inspection

- EDM: 100% inspection

- Wire-cutting: 100% inspection

- Packing: Final 100% inspection before shipment

Packaging & Delivery

Packaging: Components are coated with anti-corrosive oil and securely packed in carton boxes.

Production Time: Standard delivery is 7-15 working days for ejector pins, with specific timelines based on order quantity.

Shipping: We utilize express carriers including DHL, UPS, and FedEx (3-5 day delivery) with tracking provided. Ocean shipping available for larger quantities with economic advantages.

Frequently Asked Questions

What information is required for quotation?

Product specifications including model and size, or customer technical drawings.

How do you ensure product quality?

Our dedicated QC department monitors quality throughout the entire production process.

What if quality issues occur?

We maintain strict quality standards and manufacture to customer satisfaction requirements.

Do you test products before delivery?

Yes, we perform 100% quality control testing and provide QC reports for all mold parts.

Can you produce from samples or drawings?

Yes, we can manufacture parts according to your samples or technical specifications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!