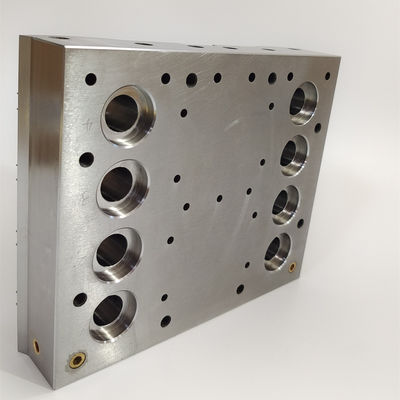

High Efficiency 4 Cavities Medical Treatment Die Steel Mold Core for Lab Petri Dish Plastic Mold Parts

Mold Core Parts Introduction

The mold core plate forms the interior of the final plastic part. Similar to the cavity, the mold core can be positioned on either plate. For complex parts such as medical injection molding products, a loose mold core insert may be required. These inserts are removed from the mold at the end of each cycle, and the part is then extracted from the insert.

By convention, the hollow (concave) portion of the cavity space is called the cavity, while the matching, often raised (convex) portion is called the mold core. Most plastic products are cup-shaped, meaning they have distinct inside and outside surfaces. The outside is formed by the cavity, and the inside by the mold core. Flat-shaped products without specific convex portions present different molding challenges, particularly for ejection. Typically, cavities are placed in the injection side mold half, while cores are positioned in the moving half to facilitate ejection.

Product Specifications

| Product Name |

Mold Core |

| Product Material |

DIN 1.2343 |

| Hardness |

52 HRC |

| Machining Process |

Milling, Rough CNC, Heat Treatment, Water Milling, Grinding, Precise CNC, W-EDM, Boring, EDM, QC |

| Tolerance |

0.002mm |

| Mold Lifetime |

1,000,000 shots |

| Standard Parts From |

HASCO, MEUSBURGER, DME, MISUMI, LKM, Fibro, Danly |

| Brand Name |

Senlan |

| Certification |

ISO9001 |

| Packaging Details |

1. Each piece wrapped with PE film

2. Placed in plastic box with foam pads

3. Locked and labeled

4. Heavy wrapping

5. Carton or wooden case

|

| MOQ |

1 piece |

| OEM/ODM/Customized |

Available |

| Pricing |

Prices depend on order quantity. Flexible & Negotiable. |

Our Manufacturing Advantages

- Quality & Consistency: 70% of products exported to European and North American markets with ISO quality control system

- Credibility & Responsibility: Management committed to maintaining long-term partnerships through quality service

- Communication & Vision: English-proficient sales team with deep understanding of European & North American market requirements

- Professional Expertise: Engineers with over 20 years experience and sales managers with 15+ years export experience

- One-Stop Service: Comprehensive product development, manufacturing, and assembly services

Company Profile

Senlan Precision Mould Parts Co., Ltd is a leading plastic mold manufacturer in China, specializing in precise tooling and high-technology mold design. We serve international markets including Poland, Ireland, Turkey, Malaysia, Iran, Jordan, Serbia and other regions.

We specialize in designing, molding and manufacturing plastic molds for medical appliances, motor vehicle accessories, building materials, household appliances, IT products, and various plastic products. Our mold division produces over 40 molds per month.

Frequently Asked Questions

Q1: What types of products can you manufacture?

We specialize in designing, molding and manufacturing plastic molds for medical appliances, motor vehicle accessories, household appliances, and various plastic products. Our mold division produces over 40 molds per month.

Q2: Do you offer mass production of plastic injection parts?

Yes, we have 8 precision injection machines ranging from 100 grams to 20000 grams capacity, capable of processing general plastic, engineering plastic and special materials. For quotations, please provide plastic components' function and material specifications.

Q3: What file formats do you require for quotation?

We accept 3D designs, 2D detailed drawings, or clear sample pictures with dimension indications for accurate quotation.

Q4: How do production quantities affect mold design?

Your quantity requirements (annual, monthly, or daily) help us determine the optimal number of cavities, select appropriate steel, and optimize mold cost efficiency.

Q5: What machine specifications should I provide?

Please provide your molding machine tonnage or injection capacity to help us calculate the optimal mold cavity configuration.

Q6: Can you accommodate specific component brand requirements?

Yes, we can accommodate special requirements for custom mold components such as hot runners, hydraulic cylinders, and other specific brands.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!