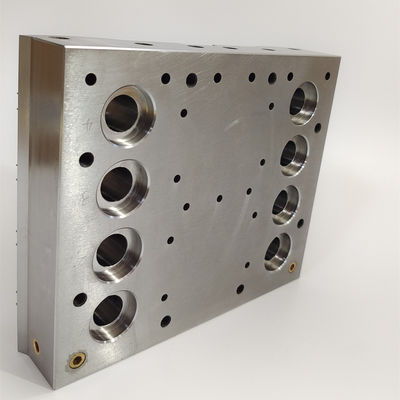

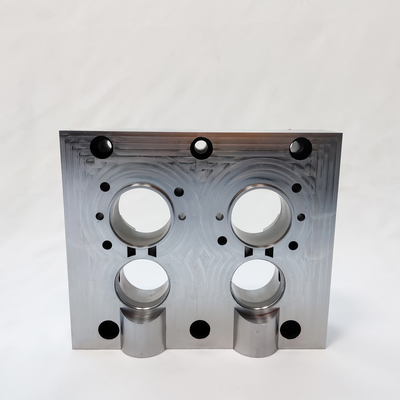

Precision Stavax High Hardness Mold Core Plate for Daily Packaging Plastic Injection

Mold Core Plate Overview

Our precision mold core plate system consists of a mold core plate and cavity plate with integrated temperature control channels in backup plates, mold core plates, and cavity plate. The complete assembly includes support pillars, ejectors, sprue bush, sprue puller, and gate components.

The mold cavity and core plates mount securely to the mold base, which fixes to platens within the injection molding machine. The front half features a support plate for mold cavity attachment, sprue bushing for material flow from the nozzle, and locating ring for precise alignment.

The rear half contains the ejection system attached to the mold core plate and support plate. During operation, the ejector bar activates the ejection system when mold halves separate, pushing the ejector plate forward to drive ejector pins into the molded part for removal from the open mold cavity.

Technical Specifications

| Product Name |

Plastic injection mold base FAI model |

| Positional Accuracy |

± 2μm for workpiece size ≤ 600mm x 300mm

± 5μm for workpiece size ≤ 1200mm x 700mm |

| Flatness |

≤ 5μm |

| Mould Base Life |

500,000 - 3,000,000 Shots |

| Material |

P20, 718, 2738, NAK80, S136, S136H, etc. |

| Mould Runner |

Hot Runner, Cold Runner |

| Mould Base Standard |

LKM, HASCO, FUTABA, DME |

| Cavity |

Single, Multi |

| Grinding |

Coarse, Fine |

| Surface Treatment |

Polishing, Texture |

| Imported Machines |

Jip Grinder, Precision Horizontal Surface Grinder, CNC, etc. |

| Design Software |

CAD, UG, PROE Files, etc. |

| Application |

Relays, Household Appliances, Cars, Electronics, Mobile Phones, etc. |

Production Process

- Evaluate mold feasibility according to customer product drawings and requirements

- Confirm manufacturing capability and request stamping equipment technical data

- Determine production plan and provide mold pricing

- Receive order notification

- Confirm product layout and material utilization

- Process 50% deposit payment

- Begin mold parts processing and production

- Produce sample products using completed mold for customer confirmation

- Adjust mold based on product qualification feedback until meeting drawing requirements

- Process final payment

- Arrange delivery after confirming transportation and packing method

Manufacturing Advantages

- 16 years specializing in silicon steel sheet high-speed stamping die manufacturing

- Largest manufacturer of high-speed stamping dies for transformers, ballasts, reactors in China

- Annual production of 160 varieties of high-speed stamping dies for silicon steel

- Fully customizable die solutions

Frequently Asked Questions

Q1. Are You A Trading Company Or A Factory?

Senlan Precision Mould is an OEM, ODM, OBM factory in Guangdong, China, specializing in plastic mold base manufacturing.

Q2. How To Get A Quotation?

Standard products: provide model + size and quantity (e.g., 4045-SCI-A90-B90 1set). Non-standard products: provide drawing, special requests, and quantity.

Q3: How Long Is Your Delivery Time?

Standard products: 3-5 days. Non-standard products: varies according to manufacturing complexity.

Q4: Do You Provide Samples? Is It Free Or Payable?

Yes, we provide samples or raw material for quality inspection. Customers bear freight costs, and some special products may require sample payment.

Q5. How Can You Guarantee Quality?

Advanced machine equipment, mature technology, and skilled workers ensure product quality. Our QC department performs thorough inspections before every shipment.

Q6. After-Sale Service

Contact us with any questions after receiving samples or products. We provide comprehensive support until complete satisfaction.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!