SKD61 Core Pins with Cooling Hole | High-Pressure Die Casting Tooling

Product Overview

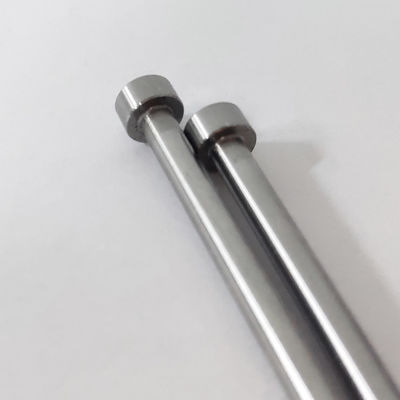

Senlan Precision offers high-quality SKD61 die steel high-pressure die casting parts with cooling hole core pins, engineered for extended service life. Designed for precision applications in various industries, these core pins are ideal for molds that require high durability, precise cooling, and excellent performance under high-pressure conditions.

Key Features & Advantages

-

Material: Manufactured from SKD61 die steel for superior durability and high-temperature resistance, ideal for high-pressure die casting.

-

Cooling Hole Design: Features an integrated cooling hole to enhance cooling efficiency and reduce cycle times, ensuring a consistent part quality.

-

Long Service Life: Engineered for prolonged durability, these core pins offer extended lifespan even under demanding molding conditions.

-

Precision Machining: Made to tight tolerances, ensuring accuracy and consistency in the molding process.

-

High-Pressure Capability: Suitable for high-pressure die casting applications, offering reliable performance in complex molds.

-

Corrosion Resistance: Coated to offer excellent resistance to corrosion and wear, ensuring long-term performance in harsh environments.

-

Customization: Available in various sizes and designs to meet specific application requirements, including customized cooling channels and thread configurations.

Applications & Industry Use

-

Packaging Industry: Used in molds for bottles, caps, and packaging components where precise cooling and long-lasting mold components are essential.

-

Medical Devices: Ideal for producing medical injection molded parts that require high precision and durability.

-

Plastic Injection Molding: Provides high-performance tooling solutions for molding complex plastic parts with high precision.

-

Electronics and Consumer Goods: Supports efficient mold performance for electronics components and consumer goods that demand consistent, high-quality production.

Mold Structure & Design Description

The SKD61 die steel core pins are designed with cooling holes strategically placed to optimize the cooling process during injection molding. This cooling feature helps maintain uniform temperature distribution, reducing cycle times and preventing defects in molded parts. The core pins are machined with precision to meet your specific design and operational needs, including customized dimensions, surface finishes, and cooling channel configurations.

Manufacturing Capability & CNC Machining Capacity

Senlan Precision leverages advanced CNC machining equipment to produce the highest quality die casting parts. Our machining capabilities include:

-

CNC Precision Machining: Utilizing state-of-the-art machinery from MAKINO (Japan) and HARDINGE (USA) for precise machining and high-quality surface finishes.

-

Advanced Cooling Design: Our engineering team optimizes the cooling channel design for maximum cooling efficiency in high-pressure die casting applications.

-

Customization: We offer fully customized core pins, adjusting sizes, shapes, cooling channels, and other features to meet specific customer needs.

-

Quality Control: Every part is inspected to ensure it meets strict quality standards, with detailed documentation provided to guarantee compliance with industry regulations.

Custom Development & OEM Cooperation Process

-

Consultation & Design Specifications: Discuss your specific needs, and review your drawings and specifications for customization.

-

Material Selection & Core Pin Design: Choose the appropriate SKD61 die steel material, and design the core pin with the necessary cooling holes and features for optimal performance.

-

CNC Machining & Precision Processing: Utilize our advanced CNC machines to create precision core pins with accurate cooling channels, surface finishes, and dimensions.

-

Inspection & Testing: In-process inspections ensure that each part meets the required tolerances, including dimensional accuracy and cooling efficiency.

-

Final Quality Check & Shipping: After final assembly and testing, the core pins are packaged securely and shipped according to your timeline.

Quality Control & Export Experience

-

Rigorous Testing: We conduct comprehensive quality control checks throughout the manufacturing process, ensuring each part meets your exact specifications and high industry standards.

-

Complete Documentation: We provide material certifications, inspection reports, and export documents for smooth delivery and compliance.

-

Global Delivery: With years of experience in exporting to international markets, we ensure secure and timely delivery worldwide.

Related Products

-

SKD61 Die Steel Core Inserts for Plastic Injection Molding

-

Cooling Core Pins for Die Casting Molds

-

Customized Core Inserts for Medical Molds

-

Precision Threaded Mold Core Pins

FAQ (Technical & Purchasing)

Q1: What makes SKD61 die steel suitable for die casting parts?

A: SKD61 is a high-quality die steel known for its exceptional wear resistance, toughness, and ability to withstand high-pressure and high-temperature environments, making it ideal for die casting applications.

Q2: Why is cooling hole design important for core pins?

A: Cooling holes ensure uniform temperature distribution during the molding process, which improves cooling efficiency, reduces cycle time, and ensures consistent part quality.

Q3: Can you customize the core pins to fit specific mold designs?

A: Yes, we offer full customization of core pins, including size adjustments, thread configurations, and cooling channel designs to meet your unique mold requirements.

Q4: How do you ensure the precision and durability of the core pins?

A: We utilize advanced CNC machining technology and rigorous inspection processes to guarantee that every core pin meets the required precision and durability standards, ensuring long-lasting performance.

Get a Quote

For customized SKD61 die steel core inserts, or to discuss your project requirements in detail, please contact Senlan Precision today. Our team is ready to provide you with the best solutions for your injection molding needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!