Product Overview

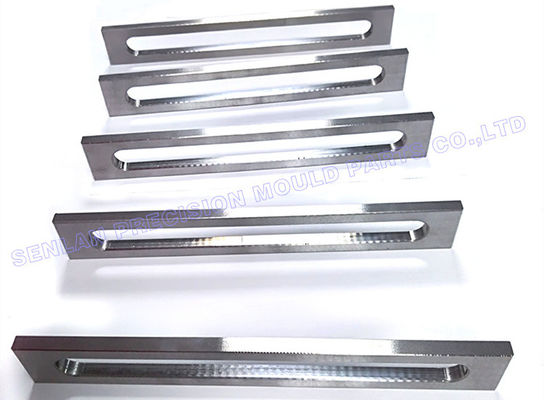

These precision CNC machined steel parts are manufactured for high-accuracy injection mould components and industrial tooling applications. Produced through CNC milling and turning processes, the parts deliver stable dimensional control, reliable mechanical strength, and consistent surface quality. All components are manufactured strictly to customer drawings and technical specifications for mould and tooling systems.

Key Features & Technical Advantages

-

Precision CNC milling and turning for tight dimensional control

-

Suitable for mould inserts, structural parts, and functional tooling components

-

High-strength steel materials with controlled machinability

-

Stable geometry for multi-cavity and long-cycle mould operation

-

Custom sizes, tolerances, and surface finishes available

-

Built-to-Print manufacturing based on customer drawings

Applications & Industry Use

-

Plastic injection mould components

-

Bottle cap and closure mould systems

-

Packaging mould structural and support parts

-

Medical consumables mould tooling

-

Industrial mould assemblies requiring high rigidity and precision

Mould Structure & Design Description

These CNC machined parts are commonly used as functional mould components, including mounting elements, support blocks, and precision interfaces within injection mould systems. Design considerations include:

-

Accurate datum surfaces for mould alignment

-

Machined slots, holes, and interfaces per mould structure requirements

-

Compatibility with multi-cavity mould layouts

-

Optimized geometry to maintain mould stability under repeated cycles

All designs are manufactured strictly according to customer-provided drawings or approved samples.

Manufacturing Capability & CNC Machining Capacity

-

CNC milling (3-axis and multi-operation setups)

-

CNC turning for rotational and stepped components

-

Precision grinding for critical tolerance surfaces

-

Tolerance capability: up to ±0.01 mm depending on structure

-

Material options: carbon steel, alloy steel, stainless steel

-

Small batch to medium-volume production support

Custom Development & OEM Cooperation Process

-

Drawing and technical requirement review

-

Machining process evaluation and feasibility confirmation

-

Sample or pilot production upon request

-

Full-scale CNC machining and inspection

-

Packaging and export-ready delivery

We support OEM / ODM / Built-to-Print projects with stable communication and engineering feedback.

Quality Control & Export Experience

-

Incoming material verification

-

In-process dimensional inspection

-

Final measurement using precision gauges and inspection tools

-

Traceable quality records for each production batch

-

Experience supplying mould components to overseas customers for long-term cooperation

Related Products (Internal Links)

-

Custom Mold Core Inserts

-

Precision CNC Turned Mold Components

-

Multi-Cavity Mold Structural Parts

-

Injection Mold Support Components

Frequently Asked Questions (FAQ)

Q1: Do you manufacture strictly according to drawings?

Yes. All parts are produced based on customer drawings or approved samples only.

Q2: What tolerance can you achieve?

Typical tolerances range from ±0.01 mm to ±0.02 mm, depending on part structure and material.

Q3: Can you support small trial orders?

Yes. We support prototype and small-batch production before mass manufacturing.

Q4: Are these parts suitable for multi-cavity moulds?

Yes. The machining accuracy and structural stability are suitable for multi-cavity mould applications.

Get a Quote

If you are sourcing custom precision CNC machined parts for injection mould components, please send us your drawings or technical requirements.

Our engineering team will provide a technical evaluation and quotation promptly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!