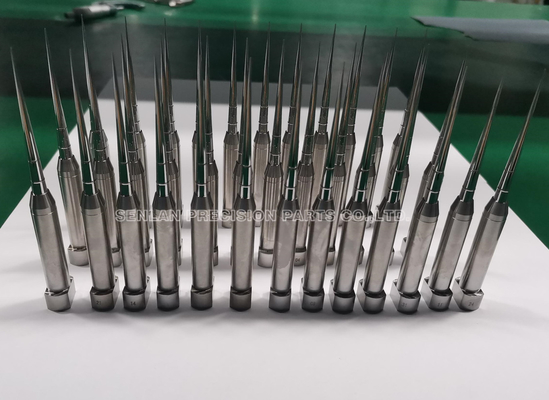

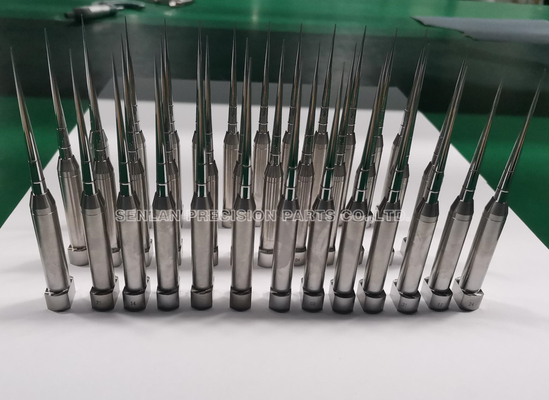

Mirror Polished M340 Mold Core Pins for Medical Applications

Mold core pins are essential components in medical injection molding processes, where precise design ensures proper functionality of end products and guarantees safety for both patients and healthcare providers. Over years of development, toolmakers have refined tolerances and perfected manufacturing processes for stainless steel mold core pins.

As medical standards continue to evolve with increasing patient safety requirements, manufacturers and toolmakers persistently research and optimize every component of medical consumables to meet the highest quality standards.

Product Specifications

| Materials |

M340 |

| Industry Standards |

DIN, JIS, AISI, GB |

| Minimum Order Quantity (MOQ) |

1 piece |

| Production Capacity |

2000 pieces per week |

| Lead Time |

7-20 days from deposit |

| Payment Terms |

T/T, PayPal, Western Union, Cash |

| Quality Control |

Hardness tester, Calipers, Altimeter, CMM, Projector, 2.5D |

| Machines/Equipment |

CNC lathes, OD Grinder, EDM, CNC Milling |

Additional Services & Information

- OEM & ODM services available

- Customized specifications

- Direct one-to-one communication

- Free samples available

- Sample orders and small orders accepted

- Shipping methods: DHL, EMS, UPS, FedEx

- Located in Dongguan City, China manufacturing base

- Custom design assistance based on requirements and applications

Technical Specifications

Tolerance

±0.005mm (customizable based on customer requirements)

Drawing Formats

PDF, DWG, DXF, IGS, STEP, etc.

Packaging

Inner packaging with recycled plastic boxes and anti-corrosive oil, outer packaging with sponge and PE bags, or customized to customer requirements.

Application Fields

Automobile parts, medical devices, daily necessities packaging, cosmetic packaging, and various industrial applications.

Company Overview

Team Philosophy

Our sales team operates on the principle that teamwork maintains leadership. Team spirit represents our core competitiveness, enabling us to lead the industry and achieve sustainable growth.

Product Range

SENLAN manufactures a comprehensive line of standard and customized components including ejector pins, punches, insert pins, cavity pins, core pins, mold cores, and various mold accessories and die parts.

Manufacturing Capabilities

As a professional OEM die casting parts manufacturer, we provide complete services including tooling design, tooling fabrication, die casting, secondary processes, precision machining, T6 treatment, finish treatments, and assembly.

Our experienced quality control team ensures we consistently meet customer requirements and exceed expectations through high quality standards, competitive pricing, and rapid response times.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!