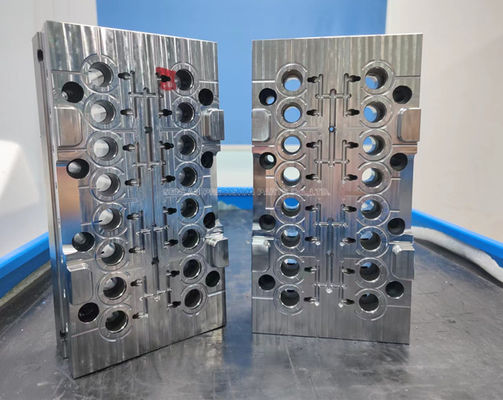

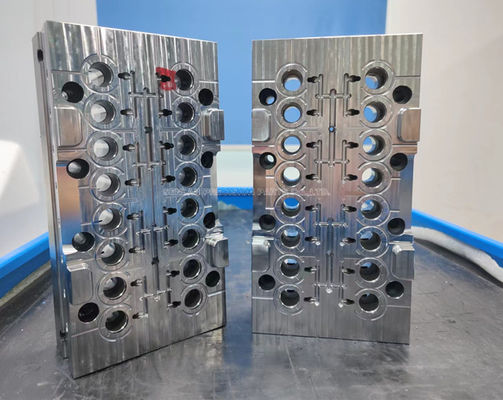

16-Cavity Precision Mold Cavity Insert for Injection Mold Tooling

The 16-Cavity Precision Mold Core Insert is a high-precision mold component designed for multi-cavity plastic injection molds used in packaging, medical consumables, and high-volume plastic production. This insert forms the core side of the mold, shaping internal features of molded plastic parts while ensuring consistent part quality across all cavities.

Product Overview

Manufactured from high-performance mold steels such as STAVAX, 1.2083, or stainless tool steels, this multi-cavity core insert is engineered to provide excellent corrosion resistance, dimensional stability, and long service life in demanding injection molding environments.

The insert integrates multiple precision-machined cavities and runner channels, enabling balanced plastic flow and efficient mass production in multi-cavity mold systems.

Key Features

- Multi-cavity 16-cavity mold design

- Precision machined core insert block

- Suitable for plastic injection mold tooling

- Integrated runner channel system

- Excellent wear resistance and corrosion resistance

- Replaceable modular mold insert design

- Machining tolerance up to ± 0.005 mm

Applications

Plastic Packaging Products

Used in molds producing packaging components such as small containers, caps, lids, and cosmetic packaging parts.

Medical Consumables

Applicable for molds producing medical disposable plastic components, including connectors, caps, and laboratory consumables.

Consumer Plastic Products

Used in molds producing precision plastic parts for household and daily-use products.

Multi-Cavity Production Molds

Ideal for high-efficiency molds designed to produce multiple parts per injection cycle.

Cosmetic and Personal Care Packaging

Suitable for molds producing cosmetic caps, lids, and packaging accessories requiring high surface quality.

Precision & Manufacturing Capabilities

- High-precision CNC milling and machining

- Precision grinding for tight tolerances

- Advanced runner channel machining

- Mirror polishing for high surface finish

- Professional heat treatment and material processing

- Precision dimensional inspection using advanced measuring equipment

We can achieve machining tolerances up to ± 0.005 mm, ensuring consistent cavity alignment and reliable mold performance.

Production Efficiency Benefits

Higher Production Output

Multi-cavity mold inserts allow molds to produce multiple plastic parts in each injection cycle, significantly increasing production capacity.

Improved Mold Maintenance

Replaceable inserts allow worn cavities or damaged sections to be replaced without rebuilding the entire mold.

Consistent Product Quality

Precision machining ensures uniform cavity geometry, improving dimensional consistency across all molded parts.

Reduced Manufacturing Cost

Modular mold inserts reduce mold repair time and lower long-term tooling costs.

Adaptability for Future Mold Modifications

Insert-based mold structures allow easy upgrades when product designs change.

Quotation Requirements

To provide an accurate quotation for custom multi-cavity mold core inserts, please provide the following information:

- Product 2D drawings or 3D CAD files

- Required number of cavities

- Mold insert dimensions

- Plastic material used for molding

- Surface finish or polishing requirements

- Expected mold life

- Quantity required

Our engineering team will review your design and recommend the most suitable manufacturing solution.

Frequently Asked Questions

What is a mold core insert?

A mold core insert is a removable mold component that forms the internal structure of molded plastic parts inside an injection mold.

Why are multi-cavity molds used?

Multi-cavity molds allow manufacturers to produce multiple parts in a single injection cycle, improving efficiency and reducing production costs.

What materials are commonly used for mold core inserts?

Common materials include STAVAX, 1.2083 stainless mold steel, H13 tool steel, and 420 stainless steel, depending on the application.

Can mold core inserts be customized?

Yes. Core inserts can be fully customized according to product drawings, cavity layout, and mold design requirements.

What industries use multi-cavity injection molds?

Industries include plastic packaging, medical consumables, cosmetics packaging, and consumer plastic products.

Looking for a Reliable Supplier of Precision Mold Inserts?

We specialize in manufacturing custom mold core inserts for multi-cavity plastic injection molds, serving customers in packaging, medical, and consumer product industries.

Contact us today to receive:

- Competitive pricing

- Professional engineering support

- Stable quality and fast lead times

Send us your drawings or project requirements to get a quotation today.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!