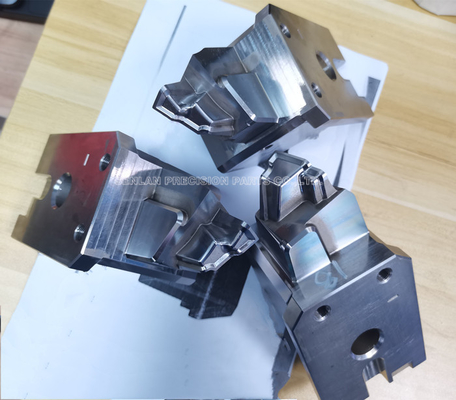

1.2738 Plug-In Slider Injection Molding for Auto Mold Parts

Precision mold parts manufactured from premium steel materials with exceptional performance characteristics and advanced design features.

Product Features

- Precision manufacturing using excellent steel materials

- Interchangeable preform mold parts for versatile applications

- Advanced heat treatment for enhanced durability

- Quick-disconnect cooling water pipes for easy maintenance

- Pendular design neck ring extends screw life

- Cavity plate mounting prevents over-extrusion damage

- Optimized hot runner system minimizes pressure loss

- Effective insulation reduces heat transfer between nozzle and mold body

- Minimized plug/socket connections for faster assembly

- Compatible with injection molding machines of all brands

Our Product Range

- Core pins, cavity pins, insert pins

- HSS punches, precision punches, special-shaped punches

- Ejector pins, ejector sleeves, two-stage ejector pins

- Guide pillars, guide bushings, guide post sets

- Slide core units, latch locks, locating series

Why Choose Our Products

- Comprehensive one-stop service solutions

- Competitive pricing structure

- Distinctive corporate culture focused on quality

- Rigorous quality control systems

- Custom solutions tailored to your requirements

- Extensive experience in mold industry applications

- Exceptional products with dedicated customer support

Company Profile

Founded in 2012, Senlan Precision Mould specializes in providing global standard mold parts including JIS, DIN, and AISI standards, along with custom-built mold components and comprehensive solutions for plastic mold and die casting mold applications. As a manufacturing factory, we offer a complete range of standard mold parts including ejector series, slide core units, latch locks, locating series, date stamps, slide retainers, cooling systems, and mold counters.

With over 15 years of industry experience, 6 manufacturing plants, and a professional team deeply knowledgeable in global standard mold parts, we possess the capability and insight to meet your most demanding requirements with competitive solutions.

Manufacturing Equipment

| Equipment Type |

Brand |

Model |

Precision |

Quantity |

Origin |

| CNC |

TAKISAWA |

NEX-108 |

0.002mm |

4 |

Japan |

| WEDM |

SODICK |

AQ400LS |

0.003mm |

2 |

Japan |

| CHMER |

CHMER |

G435 |

0.005mm |

1 |

Taiwan |

| EDM |

CREATOR |

CJ-235 |

0.005mm |

4 |

Taiwan |

| Mirror EDM |

SODICK |

Sodick-AM30LS |

0.003mm |

2 |

Japan |

| MAKIMO |

MAKIMO |

EDGE2 |

0.002mm |

1 |

Japan |

| Desktop lathe |

JINGCHENG |

YB-15 |

0.05mm |

4 |

China |

| Desktop lathe |

JINGCHENG |

YB-25 |

0.05mm |

2 |

China |

| OD grinder |

HOTMAN |

FX-03 |

0.002mm |

5 |

China |

| ID grinder |

HOTMAN |

FX-05 |

0.002mm |

3 |

China |

| Centerless grinder |

HOTMAN |

FX-12S |

0.001mm |

2 |

China |

| Surface Grinder |

SHUGUANG |

614 |

0.001mm |

4 |

China |

| Surface Grinder |

SHUGUANG |

618 |

0.001mm |

2 |

China |

| EDM drilling |

ZENBANG |

ZB-03 |

0.01mm |

1 |

Taiwan |

| Miller |

TOPINR |

AVA |

0.01mm |

2 |

Taiwan |

Packaging Details

Outer packaging: Cartons with foam packing or wooden boxes

Inner packaging: Components packed in sponge with plastic bag protection

Payment & Shipping

Payment methods: T/T, PayPal, Western Union (50% deposit, balance before shipment)

Shipping carriers: DHL, TNT, FedEx available

Delivery options: Sea freight or air freight

Frequently Asked Questions

What information do you need for quoting?

Product standard: model + size, or customer technical drawings.

How do you ensure product quality?

We maintain a dedicated QC department that monitors quality throughout the entire production process until final inspection.

What if I receive poor quality products?

We maintain strict quality standards and manufacture products to your complete satisfaction, ensuring quality issues are extremely rare.

Do you test products before delivery?

Yes, we perform 100% quality control testing and provide QC reports for all mold parts before shipment.

Can you produce custom parts from samples or drawings?

Yes, we can manufacture parts according to your samples or technical drawings.

Product Images

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!