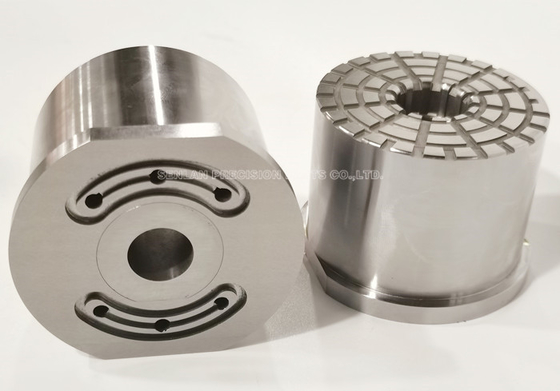

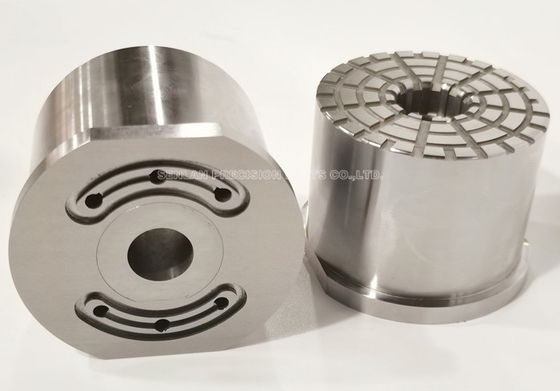

Customized Plastic Mould Part Precision Core Inserts

Manufactured from premium SKD-61 hotwork die steel, our precision core inserts are engineered for packaging and container applications. Features include hot forged heads with stress relief for uniform grain flow and high tensile strength.

Product Specifications

| Material |

SKD61 |

| Hardness |

50-52HRC |

| Heat Treatment |

Available |

| Service |

Made-to-order |

| Surface Treatment |

/ |

| Closest Tolerance |

±0.01mm |

| Polishness |

Ra0.6 |

| Axiality |

0.01mm |

| Verticality |

0.01mm |

Surface Enhancement Options

Surface can be ion nitride coated to HV 1000°±100° hardness. Core vacuum pins can be hardened to HRC 52°±2°. Alternative steel materials available upon request.

Product Range

Our comprehensive product line includes plastic mold core pins and inserts, movable core components, and specialized components for various industrial applications.

Manufacturing Capabilities

- Manufacturing & inspection capacity in steel, stainless and copper materials

- Precision mould parts including cavity pins, core pins, punches, ejector sleeves

- CNC machining parts and comprehensive machining services

Processing Services

CNC machining, CNC Milling, Sodick EDM, Sodick Wire-cut, OD grinding, ID grinding, Surface grinding, Thread grinding, Polishing

Industry Applications

Medical, Packaging, Aerospace, Electronic, Automotive, Cosmetics, Daily necessities packaging

Why Choose Our Precision Core Inserts

Specialized manufacturer with 8+ years experience in precision core pins and inserts

Advanced production equipment operated by experienced technicians

Extensive OEM and ODM experience for custom requirements

Competitive pricing with quality assurance and fast delivery

Technical Advantages

- Highly polished finish: 6-8 micro finish

- Precision form ground to close diameter tolerance: ±0.005mm

- Common fractional sizes available up to 3 1/2″ long

- M-2 high speed steel: 60-63 Rockwell C

- Custom sizes available up to 1″ diameter

- Custom hardness RC 64-65 and triple drawn available on request

Ordering Process

Submit drawing, sample, or series number (NDA available for confidential files)

We evaluate requirements and provide quotation

50% deposit to confirm order, balance before shipment

Production timeline: 10 working days standard, 7 days for samples

Flexible shipping options: express, air, or sea freight

Required Information for Inquiry

- Product drawings or samples

- Required material specifications

- Dimensions and tolerance requirements

- Hardness and surface treatment needs

- Order quantity estimates

Business Terms

Payment: T/T, Paypal, Western Union (50% deposit, balance before shipment)

Packaging: Anti-corrosive oil coating with carton box packaging

Shipping: DHL, TNT, Fedex available

Frequently Asked Questions

When can I get the price?

We typically provide quotations within 24 hours of receiving your inquiry. Urgent requests receive priority handling.

How long is the lead time for mold parts?

Standard lead time is 20-30 days. Simple, smaller parts can be completed in 12 days depending on complexity and size.

I have no 3D drawing, how should I start the new project?

We can create 3D drawings from your physical samples to initiate the project.

How do you ensure product quality before shipment?

Quality control inspection before each shipment. Third-party inspections welcome. Production process videos available upon request.

Can I get discounts?

Yes, we offer reasonable discounts for large orders, repeat customers, and frequent business partners.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!