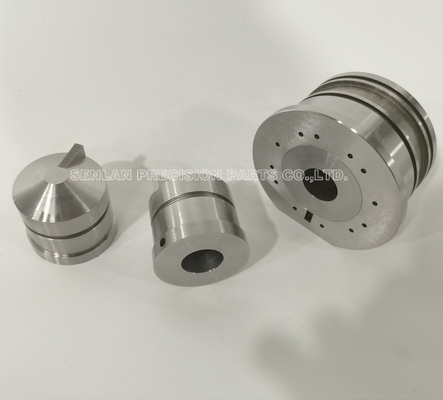

High Precision Mould Parts Mold Core Mold Components For Plastic Mould

The foundation of the injection molding process is the mold itself. The most common style is the straight-pull mold, which consists of two halves: a core and a cavity. These mold halves, typically manufactured from steel or aluminum, are secured together in the molding press using mechanical clamps or hydraulic pressure. Molten plastic is then injected to fill the cavity and form the desired part. After cooling, the mold halves are separated.

Mold Half Functions

Core (B Side): The interior or non-cosmetic side of the part, containing the ejection mechanism that releases the completed part from the mold.

Cavity (A Side): The void that molten plastic fills to form the final part shape, typically creating the cosmetic exterior surface.

Mold Components Specifications

| Specification |

Details |

| Materials |

1.2343 |

| Industry Standards |

DIN, JIS, AISI, GB |

| Minimum Order Quantity (MOQ) |

1 piece |

| Production Capacity |

2000 pieces per week |

| Lead Time |

7-20 days from deposit |

| Payment Terms |

T/T, PayPal, Western Union, Cash |

| Quality Control Equipment |

Hardness tester, Calipers, Altimeter, CMM, Projector, 2.5D |

| Machinery/Equipment |

CNC lathes, OD Grinder, EDM, CNC Milling |

| Additional Services |

OEM & ODM, Customized Specifications, One-to-One Communication, Free Samples |

Additional Information

- Sample orders and small quantities accepted

- Delivery methods: DHL, EMS, UPS, or FedEx

- Located in Dongguan City, China's manufacturing base

- Custom design services available based on customer requirements and product applications

Technical Specifications

Tolerance

±0.005mm (customizable to customer requirements)

Drawing Formats

PDF, DWG, DXF, IGS, STEP, etc.

Packaging

Inner packaging with recyclable plastic boxes and anti-corrosive oil, outer packaging with sponge and PE bags, or as per customer requirements.

Application Fields

Automobile parts, medical equipment, daily necessities packaging, cosmetic packaging, etc.

Company Overview

Team Philosophy

Teamwork is our core competency. Only through strong team collaboration can we maintain leadership and achieve long-term success.

Main Products

SENLAN manufactures a comprehensive range of standard and customized ejector pins, punches, insert pins, cavity pins, core pins, mold cores, and other mold accessories and die parts.

Service Commitment

- Professional advice and operational support

- 24/7 online customer service

- Comprehensive pre-shipment inspection

- Excellent after-sales service

- Strict quality control standards

- Flexible shipping terms: EXW, FOB, CIF

- OEM and ODM services available

Manufacturing Capabilities

Senlan Precision Parts Co., Ltd is a professional manufacturer of customized precision mold parts. Our comprehensive services include tooling design, tooling fabrication, secondary processing, precision machining, T6 treatment, finish treatment, and assembly. Our experienced quality control team ensures we meet customer requirements and satisfy demands with high quality, competitive pricing, and quick response times.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!