What Is Core Insert Moulding?

Core Insert moulding involves injecting plastic in a mould onto a component made from a different material. this component is called the Core Insert. It is often made from steel or some other type of metal. the advantage of this technique is that the Core Insert is entirely covered by the injected plastic, and thus optimally integrated. you might think that placing the Core Inserts inside the injection-moulding machine takes a lot of time, but that is not the case. At Rompa Group, this process is fully automated

The Difference For Core Insert And Outsert Moulding

The injection-moulding process for Core Insert and Core Outsert moulding is largely the same as for “standard” injection moulding. the standard process is as follows:

An injection-moulding machine injects molten plastic pellets into a mould

The plastic solidifies with the help of a cooling system

The press opens and the plastic components are ejected from the mould

The difference: with insert and outsert moulding, you first place a metal component in the mould before closing it

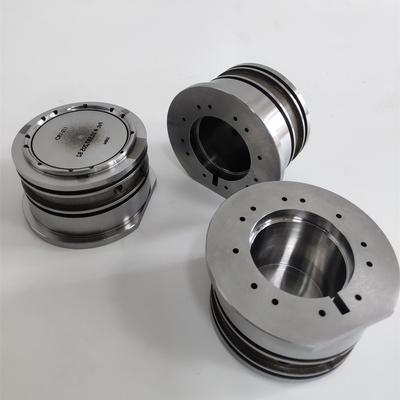

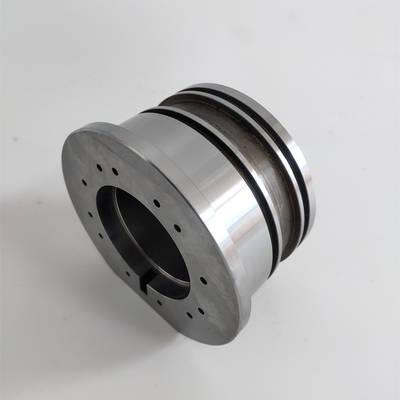

Specification:

| Brand |

Senlan |

| Technical Experience |

With more than 15 years experience |

| Production Range |

- Specilized in producing Plastic Mold Part which widely used on Cosmetics, Daily Packaging, Medical Device

- Besides, customized services availble here

|

| Closest Tolerance |

+ - 0.002 mm/+ -0.01mm |

| Material |

Carbide, SKD11, SKD61, HSS, SUJ2, Stavax, Bohler ect |

| Hardness |

45-68,or as per need |

| Surface Treatment |

TiCN, TiN, Tiain,Ticrn, Nitrided, DLC, Black oxygened etc available (as customer's requirments) |

| Shape |

Round, Rectangular, Oblong etc |

| Consistent Quality Control |

Parts are made by our experienced staffs that can control the parts to exact dimensions in the process of production. On the other hand, our experienced QCs inspect all the parts thoroughly which can ensure 100% high quality products sent to you! |

| Delivery |

3-7 working days |

| Payment Terms |

T/T, Western Union, PayPal |

| Delivery Way |

DHL, UPS, EMS, FEDEX |

| Shipment |

Sent out after payment settled |

Engineering Capabilities Include:

1.Parts design

2.R&D products

3.Prototype design and production assembly

4.Reputable design software used for all design work

5.Fast automatice remould design

6.Mould design with a team of experienced specialists

Our Service:

1. We'll offer unique solutions to your products with competitive price, good quality and best service for precision SKD61 mould parts inserts mold core

2. The quotation will be provide you in 24 hours after we get your drawings in format PDF or 3D,or samples

3. Small quantity is acceptable

4. Fast sample making. We can finish the sample in 3 days if the parts don't need any surface treatment

5. The delivery time is 3-15 days generally,it depends on the quantity and surface treatment

6. Full inspection

FAQ:

Q1: Are You Trading Company Or Manufacturer?

A: We are factory

Q2: How Long Is Your Delivery Time?

A: Generally it is 1-3 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity

Q3: What Is Your Quote Elements?

A: Product standard: model + size, or customer Drawing

Q4: How Can You Ensure The Quality?

A: We have QC department to control the quality from the begining of production until goods finish

Q5: If You Make Poor Quality Goods, Will You Refund Our Fund?

A: As a matter of fact, we wont take a chance to do poor quality products. Meanwhile, we manufacture goods quality products until your satisfaction

Q6: Do You Test All Your Goods Before Delivery?

A: Yes, we have 100% QC test and QC report for mold parts before delivery

Q7: Can You Produce According To The Samples Or Drawings?

A: Yes, we can produce punch by your samples or technical drawings

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!