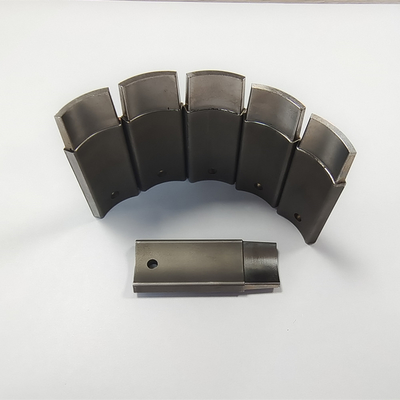

Single Cavity Injection Mould Brass Core Insert Plastic Tooling With Electrodes Processing

High Hardness Brass Core Insert Plastic Tooling With Electrodes Processing For Single Cavity Injection Mould

Advantages of Core Insert Technology

- Easy Mold Modification: Pre-installed core inserts allow for quick modifications by simply replacing inserts when design changes are required

- Enhanced Exhaust Capability: Strategic core insert placement utilizes matching gaps for superior mold exhaust performance

- Simplified Processing: Reduces complexity in machining, polishing, and plastic filling for deep cavity areas

- Material Efficiency: Optimizes mold material usage by reducing core height requirements in elevated sections

- Extended Mold Lifespan: Replaceable inserts protect critical wear areas, significantly increasing overall mold durability

Product Specifications

| Brand |

Senlan |

| Material |

1.2344, 1.2312, SKD61, S136, Stavax, Bohler and more |

| Standard |

HASCO, DME, MISUMI and more |

| Runner |

Cold/Hot Runner |

| Certification |

ISO 9000 |

Ordering & Payment Details

| MOQ |

1 set |

| Lead Time |

3-10 weeks for samples (based on requirements) |

| Production Lead Time |

2-5 weeks (based on order quantity) |

| Payment Terms |

50% T/T deposit against PO, balance 50% T/T against delivery |

| Port of Loading |

Shenzhen port |

Our Services & Advantages

- Customized OEM services and small batch purchasing with fast response times

- High-quality environmental protection materials with guaranteed performance

- Comprehensive product specifications and diverse offerings

- Renowned for fine quality manufacturing standards

- Customer-first approach with fast response within one working day

- Competitive pricing without compromising quality

- Professional production team for logo, color, and pattern customization

- Flexible solutions for individual customer needs with negotiable pricing

Order Processing Workflow

| Step |

Process |

Content |

Time |

| 1 |

Receive Inquiries |

Confirm customer needs |

1 Day |

| 2 |

Process Order |

Confirm customer order details |

- |

| 3 |

Production Start |

Raw material ordering and process arrangement |

1-3 Days |

| 4 |

Quality Control |

Comprehensive testing with CMM and manual inspection |

10-30 Days |

| 5 |

Packaging |

Custom packaging per customer requirements |

1-3 Days |

| 6 |

Shipping |

Outbound from Shenzhen |

1-3 Days |

| 7 |

Acceptance |

Product acceptance |

- |

Company Profile

We specialize in precision plastic mold components including insert blocks, guide pillars, guide sleeves, barrel thimbles, wear resistant blocks, positioning blocks, springs, and related parts. Since our establishment, we have consistently delivered high-precision products and efficient services. Our team of professional technical personnel operates state-of-the-art equipment from Swiss and Japanese manufacturers, ensuring superior quality standards. We welcome inquiries from customers worldwide.

Frequently Asked Questions

Q: Are you a trading company or a manufacturer?

A: We are a factory with direct manufacturing capabilities.

Q: How long is your delivery time?

A: Typically 15-30 days, depending on order quantity and specifications.

Q: Do you provide samples? Are they free or extra?

A: Yes, we provide samples at very competitive pricing.

Q: What information is required for a quote?

A: Please provide product standards, model specifications, dimensions, or technical drawings.

Q: How do you guarantee product quality?

A: Our dedicated quality control department monitors production from start to finish, ensuring consistent high standards.

Q: What if the product quality is unsatisfactory? Can we get a refund?

A: We maintain rigorous quality standards and are committed to customer satisfaction. For detailed quality assurance information, please contact us directly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!