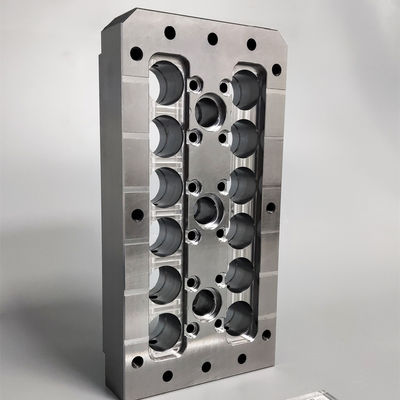

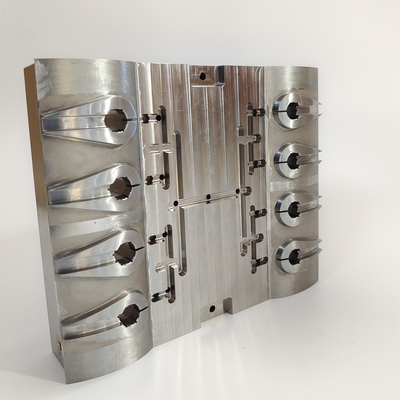

High Precision HSS Syringe Mold Core Tin Coated

Professional laboratory pipette tip injection molding components with tin coating for enhanced performance and durability.

Application Description

Our mold core retainer plate is manufactured from high-quality alloy mold steel, typically left in a soft state to prevent distortion during the hardening process. The plate features precisely drilled water lines with tapped inlets and outlets for pipe fittings, along with eight retainer screw taps for secure mounting.

Hardened and ground guide pin bushings with retaining shoulders are mounted in the plate, which is ground to match cavity block thickness. A relief is turned outside the area required for closing off runners and landing ejector return pins, maximizing unit pressure to hold the mold securely closed.

The center of the plate includes a bored hole for the sprue bushing and an undercut cold slug and sprue ejector pin hole to maintain proper sprue slug retention until mold opening. Additional features include water line drilling, four retainer screw taps for backing plate attachment, and clearance holes for three ejector return pins.

Six runners are strategically cut in the core retainer to ensure optimal material flow, with proper alignment achieved through simultaneous boring of retainer plates for perfect cavity and core alignment.

Product Specifications

| Product Name |

Stamping Die Core for Stator and Rotor Mould |

| Tooling Steel Material |

Carbide (CD650, V3, KD20), ASP-23, ASP-60, S55C-45#55, SKD11 (material selection assistance provided) |

| Mold Base Steel |

S45C (material selection assistance provided) |

| Mold Standard Components |

HASCO, MISUMI, Meusburger, DME, etc. |

| Die Concept |

2-Plate Die, 3-Plate Die, Module Die |

| Mold Life |

50 Million to 300 Million Cycles (depending on material and requirements) |

| Stamping Products |

PC Terminal, Power Terminal, Press-Fit Terminal, Lead Frame, SIM Spring, Connector Shield, Battery, Metal USB Shell, Custom Stamping |

| Surface Finish |

Texture Hatching, EDM Hatching, Plating, Polishing, Diamond Polishing, Mirror Polishing |

| Delivery Time |

25-30 Working Days (after 50% down payment) |

| Payment Terms |

T/T, L/C, Western Union, D/A, D/P, Paypal |

| Machining Centers |

High Speed CNC, Wire Cutting, EDM, Grinder, Great Grinder, CNC Milling, Drilling and Milling, Stamping Punching Machines, Injection Machine, Inspection |

| R&D Services |

Drawing Design, Mold Drawing Revision, Production Time and Quality Control with ERP System |

| Production Capabilities |

Pilot Run Production and Molding Production |

Company Profile

Senlan Precision Mould Parts Co., Ltd specializes in R&D, design, and manufacturing of precision molds, offering comprehensive one-stop services from product design and mold manufacturing to assembly and mass production solutions. Founded in 2006 and located in Chang'an Town, Dongguan City, we possess core technologies in mold development, design, manufacturing, and injection molding.

Our expertise spans automotive molds, daily necessities molds, household appliances molds, turnover box molds, and tray molds. We provide design recommendations to optimize final product structures and can manufacture molds meeting international standards including HASCO, DME, and Misumi specifications. Through continuous R&D investment and advanced ERP management systems, we maintain strong global competitiveness while serving customers worldwide.

Frequently Asked Questions

Are you a manufacturer or trading company?

We are a professional mold manufacturer founded in 2006.

Where is your company or factory located?

We are located in Chang'an Town, Dongguan City, Guangdong Province.

Can you design according to my drawing?

We provide complimentary product and mold design services, delivering complete 2D & 3D product and mold files after order confirmation.

What kind of mold parts can you make?

We manufacture all types of injection mold parts with extensive experience in complex components.

What file formats can you accept?

We accept DXF, DWG, IGS, IGES, STP, PRT, X_T, and PDF file formats.

What kind of steel do you use?

We utilize P20, P20 (H), 718, 718 (H), 2738, 2738 (H), H13, NAK 80, 2344, S136, 4Cr13, S55C, and C45# steel grades.

What materials do you use for mold inspection and production?

We work with PP, PC, PS, PE, HDPE, POM, PA6, PA66, PA6+GF, ABS, TPU, TPE, PVC, SMC, and BMC materials with extensive parameter optimization experience.

How do you send samples?

Sample delivery costs are included in our pricing, with shipping via DHL, UPS, EMS, FedEx, or TNT courier services.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!