Corrosion-Resistant Mold Cores | Custom Inserts for Disinfectant Spray Pumps

Product Overview

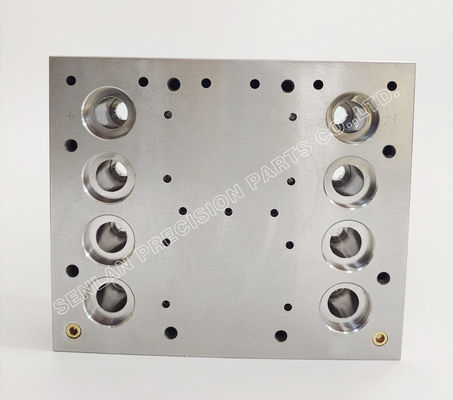

Senlan Precision specializes in the manufacturing of customized mold cores and mold inserts for plastic disinfectant spray pump injection molds. These components are produced strictly according to customer drawings, focusing on dimensional accuracy, surface finish stability, and long-term mold performance. Our solutions are suitable for high-cycle packaging molds where consistency and interchangeability are critical.

Key Features & Technical Advantages

-

Built-to-Print manufacturing based on customer drawings or 3D models

-

Designed for plastic disinfectant spray pump mold applications

-

High dimensional accuracy with stable tolerance control

-

Optimized surface finish to support smooth plastic flow and part release

-

Compatible with multi-cavity and high-output injection mold structures

-

Replaceable mold core and insert design for extended mold service life

Applications & Industry Use

Customized mold cores and inserts manufactured by Senlan Precision are widely used in:

-

Disinfectant spray pump injection molds

-

Trigger sprayer and pump component molds

-

Liquid dispensing and closure systems

-

Packaging molds for hygiene and cleaning products

-

Medical and laboratory fluid handling components

All applications focus on industrial packaging and medical tooling, not finished consumer goods.

Mold Structure & Design Description

Mold cores and inserts for spray pump molds are typically designed as precision functional components within complex mold assemblies. Key design considerations include:

-

Accurate core geometry for internal flow channels and sealing features

-

Insert alignment to ensure concentricity and repeatability

-

Wear-resistant design for high-frequency injection cycles

-

Compatibility with existing mold bases and cavity layouts

Senlan Precision manufactures components strictly according to confirmed designs without altering customer specifications.

Manufacturing Capability & CNC Machining

Senlan Precision operates advanced precision machining equipment, including MAKINO (Japan) and HARDINGE (USA) CNC systems, to ensure consistent quality.

Manufacturing capabilities include:

-

High-precision CNC milling and turning

-

EDM machining for complex internal features

-

Surface grinding and controlled polishing

-

Heat treatment coordination based on material requirements

-

Full in-process and final dimensional inspection

All machining processes are controlled to meet drawing-defined tolerances.

Custom Development & OEM Cooperation Process

We follow a standardized OEM / Built-to-Print workflow:

-

Drawing and technical requirement review

-

Manufacturing feasibility confirmation

-

Precision machining and controlled processing

-

Dimensional inspection and quality verification

-

Packaging and export shipment

We support long-term cooperation for mold maintenance, spare parts, and replacement inserts.

Quality Control & Export Experience

Quality control is integrated throughout the manufacturing process:

-

Raw material verification

-

In-process dimensional monitoring

-

Final inspection before shipment

-

Optional inspection reports upon request

With extensive export experience, Senlan Precision supports international customers with stable communication, documentation, and delivery reliability.

Related Products

-

Injection mold core pins and cavity inserts

-

Multi-cavity mold components for pump and closure systems

-

Precision sleeves, ejector pins, and mold wear parts

-

Customized mold inserts for packaging and medical molds

All related products are available on a customized / OEM / Built-to-Print basis.

Technical FAQ

Q1: Do you provide standard mold cores or inserts?

No. All mold cores and inserts are manufactured according to customer drawings.

Q2: Can you match existing mold components?

Yes. Replacement cores and inserts can be manufactured to match existing molds.

Q3: Are multi-cavity molds supported?

Yes. Our components are suitable for both single-cavity and multi-cavity mold systems.

Q4: Do you modify customer designs?

No. We manufacture strictly based on approved drawings and specifications.

Request a Quotation

For custom mold cores and mold inserts for plastic disinfectant spray pump injection molds, please provide your drawings or technical requirements.

Our engineering team will evaluate feasibility and respond with a detailed quotation and lead time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!