Custom Medical Interface Mold Parts & Precision PET Preform Components | Zero-Defect Tooling for Cleanroom Molding

Elevating Medical & Packaging Standards through Micron-Precision

Where Biological Safety Meets High-Speed Manufacturing Efficiency

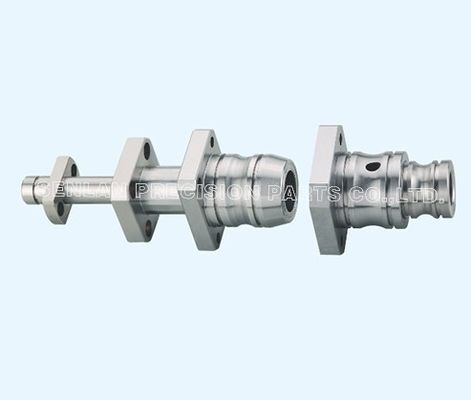

In the sectors of Medical Devices and PET Preform packaging, the margin for error is zero. Senlan Precision manufactures High-Precision Interface Mold Parts and Multi-Cavity Preform Components that adhere to the strictest global standards.

Our mission is to help molders achieve ultra-fast cycle times while maintaining 100% part consistency, ensuring your production line exceeds ISO 13485 and food-grade compliance requirements.

Solving the Critical Challenges of Medical & Packaging Molders

-

Absolute Material Purity for Cleanroom Integrity

-

The Issue: Trace impurities in mold steel can lead to micro-pitting and oxidation, contaminating sensitive medical interfaces.

-

Our Solution: We exclusively use premium STAVAX ESR, M333, or Mirrax stainless steels. Combined with vacuum heat treatment, our components offer superior corrosion resistance, eliminating the need for anti-rust agents in cleanroom environments.

-

Sub-Micron Consistency for Multi-Cavity Synchronization

-

The Issue: Dimensional variations across cavities cause uneven wall thickness in PET preforms and flash in medical connectors.

-

Our Solution: Utilizing MAKINO high-speed machining and high-precision grinding, we maintain tolerances within ±0.002mm. This ensures 100% interchangeability across 96+ cavity systems, minimizing mold setup time and balancing melt flow perfectly.

-

High-Performance Surface Engineering for Rapid Ejection

-

The Issue: Part sticking and gas trap buildup lead to aesthetic defects and increased cycle times.

-

Our Solution: We provide SPI-A1 Mirror Polishing (Ra 0.02μm) and specialized DLC (Diamond-Like Carbon) coatings. These treatments reduce the friction coefficient and material buildup, allowing for "dry running" without lubrication and faster part release.

Technical Specifications & Engineering Capabilities

| Feature |

Technical Excellence |

Target Application |

| Material |

STAVAX ESR, AISI 420, M333, Beryllium Copper |

Medical Consumables & PET Packaging |

| Precision |

Dimensional Tolerance ±0.002mm |

High-Density Interface Connectors |

| Concentricity |

0.003mm TIR (Total Indicator Reading) |

PET Preform Cores & Neck Rings |

| Surface Finish |

Mirror Polished Ra 0.02 - 0.05μm |

Optical Grade Medical Surfaces |

| Hardness |

50 - 54 HRC (Vacuum Hardened) |

Long-Life High-Cycle Molds |

| Coatings |

DLC, CrN, TiN (PVD Grade) |

Anti-Wear & Lubrication-Free Molding |

Core Application & Industry Expertise

Our precision components are the silent engines behind:

-

Medical Interfaces: Luer locks, IV connectors, syringe components, and diagnostic cartridges.

-

PET Preform Tooling: Cores, cavities, neck rings, and gate inserts for beverage and pharma packaging.

-

Laboratory Labware: Multi-well plates, pipette tips, and centrifuge tubes.

-

Dose Delivery Systems: Inhaler components and insulin pen internal parts.

The 5 Strategic Advantages of Partnering with Senlan

As an OEM partner for global medical and packaging molders, we provide:

-

ISO-Based Quality Documentation: Every shipment is accompanied by a Material Traceability Certificate and a CMM Inspection Report.

-

DFM Review for Tooling Longevity: Our engineers analyze parting lines and cooling efficiency to prevent premature component wear.

-

Mirror Polishing Mastery: Expertise in achieving optical-grade surfaces without compromising critical geometric tolerances.

-

Clean Machining Environment: Strict control over lubricants and processing fluids to ensure no heavy metal contamination for medical parts.

-

Global Interchangeability: Precision-engineered to fit seamlessly into Husky, Netstal, and other premium mold bases.

FAQ – Technical Solutions for High-Precision Tooling

Q: Can you guarantee 100% interchangeability for a 128-cavity preform mold?

A: Yes. By using dedicated fixtures and CNC-controlled grinding processes, we ensure that every core or cavity is a "clone" of the master design within ±0.002mm.

Q: How do you prevent "Rust Pitting" in STAVAX parts?

A: We use genuine ESR (Electro-Slag Refining) grades, which have extremely low impurity levels, followed by a specific vacuum quenching process to maximize chromium distribution for peak corrosion resistance.

Q: Do you support small-batch replacement orders for medical molds?

A: Absolutely. We understand the urgency of mold repair. We can produce high-precision replacement inserts from your original 3D data with rapid global shipping.

Request a Technical Quote & Compliance Review

Protect your production yield with verified precision. Send your STEP, DWG, or PDF drawings to the Senlan Precision engineering team for an immediate technical evaluation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!