Product Overview

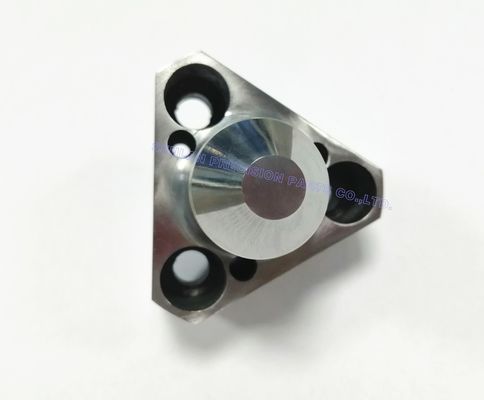

Senlan Precision manufactures high-precision CNC machined parts designed specifically for the medical and cosmetics industries. With exceptional verticality of 0.01mm, these components are made to meet the stringent tolerances required for applications in medical devices and cosmetic packaging. All parts are tailored according to your specific drawings, ensuring reliability and repeatability in high-demand environments.

Key Features & Advantages

-

Verticality Accuracy of 0.01mm

Achieve precise verticality with tight tolerance control, perfect for medical and cosmetic parts where dimensional accuracy is critical.

-

Customized to Your Specifications

Built-to-print manufacturing ensures that every component is produced according to your design and material requirements.

-

High Material Quality

Materials selected for machining offer the strength, durability, and resistance required for both medical and cosmetic applications.

-

Consistent Performance

Parts are designed for consistent performance, ensuring repeatable precision over extended production cycles.

-

Long-Lasting Durability

Machined components are built to withstand demanding environments, offering long service life and resistance to wear.

Applications / Industry Use

-

Medical Device Components

Used in precision medical instruments, requiring high dimensional accuracy for functionality and safety.

-

Cosmetic Packaging

Precision parts for cosmetic packaging, such as lipstick tubes, bottles, and other intricate packaging components, that require uniformity and reliability.

-

Injection Molding Components

Parts used in injection molding tools for both medical and cosmetic applications, with strict adherence to tolerances.

Mould Structure & Design Description

-

Functionality

These precision CNC machined parts function as integral components in injection molds, ensuring accurate molding performance. Key components include mold cores, cavities, and other intricate details that support product formation.

-

Tolerance Control

Designed and manufactured with a high degree of precision, ensuring verticality of 0.01mm, essential for high-accuracy applications.

-

Material Properties

Material selection prioritizes strength, durability, and biocompatibility for medical uses, while also meeting the aesthetic and functional needs of cosmetic products.

Manufacturing Capability & CNC Machining

-

CNC Milling and Turning

Utilizing advanced CNC equipment, we provide precision milling and turning services, enabling complex shapes and high-precision finishes.

-

EDM Machining

For intricate, detailed parts with complex geometries, Electrical Discharge Machining (EDM) is used to achieve superior accuracy.

-

Consistent Quality Control

Continuous monitoring and testing during production ensure the parts meet the highest standards of quality and precision.

Custom Development / OEM Cooperation Process

-

Initial Consultation and Drawing Review

Provide detailed drawings and specifications for an initial assessment and project planning.

-

Production and Prototyping

Custom machining and prototyping to meet your specific requirements, including material selection and surface finishes.

-

Precision Machining

High-precision CNC machining, turning, and EDM are employed to manufacture parts to exact tolerances.

-

Quality Assurance

Comprehensive inspection and testing, including dimensional analysis and material verification, ensuring the parts meet the required standards.

-

Delivery and After-Sales Support

Timely delivery of precision components, along with ongoing technical support and consultation.

Quality Control & Export Experience

-

Dimensional Inspection

All components are thoroughly inspected for dimensional accuracy, including verticality, surface finish, and overall geometry, ensuring compliance with customer requirements.

-

Material Traceability

Full traceability from raw materials to finished components, ensuring quality and consistency throughout the production process.

-

Global Export Capability

Senlan Precision has extensive experience delivering precision components to international markets with reliable shipping and export documentation.

Related Products (Internal Links)

-

Precision CNC Mold Inserts

-

Injection Molding Components

-

Medical Mold Parts

-

Cosmetic Packaging Components

Frequently Asked Questions (FAQ)

Q1: Can I get a sample before placing a large order?

Yes, we offer prototype services for your parts, allowing you to review design and functionality before mass production.

Q2: What materials are available for medical parts?

We provide a range of materials suitable for medical applications, including stainless steel, biocompatible plastics, and other high-quality alloys.

Q3: What tolerances can you achieve in CNC machining?

We can achieve tight tolerances as precise as ±0.01mm, depending on the part geometry and specifications.

Q4: Can you handle large-scale production runs?

Yes, Senlan Precision can manage both small batch and large-scale production, ensuring consistency across all quantities.

Q5: Do you provide inspection and testing reports?

Yes, detailed inspection reports are provided, including dimensional measurements and material certifications.

Request a Quote

To get a personalized quote, please share your drawings, material specifications, and quantity requirements.

Senlan Precision will respond promptly with a detailed quotation and estimated lead time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!