Product Overview

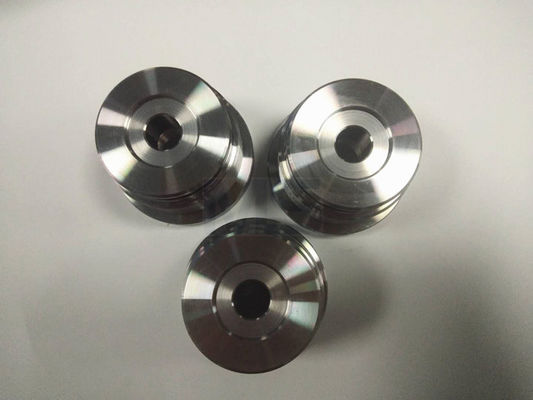

The Accuracy Plastic Injection Molding Parts with Polished Surface Treatment are precision-manufactured components designed for use in plastic injection molds. These parts are built to provide high performance in molding operations, offering excellent dimensional stability and smooth surface finishes. Custom solutions featuring threaded connections are available for diverse industrial applications.

Key Features & Advantages

-

Material: High-Quality Steel for Durability

Utilizes robust materials designed for extended mold life and high-volume production.

-

Precision CNC Machining

Manufactured with tight tolerances to ensure dimensional accuracy and reliable performance.

-

Polished Surface Treatment

Smooth and corrosion-resistant surfaces for enhanced mold performance and easy part release.

-

Custom Threading and Sizing

Offers threading options to suit specific client requirements and enhance mold assembly.

-

Built-to-Print

Completely customizable production based on customer drawings and technical specifications.

Applications & Industry Use

-

Packaging Molds

Ideal for mold components used in packaging, including bottle caps, closures, and containers.

-

Medical Device Manufacturing

Suitable for molds used in producing medical equipment, such as syringes and other disposable items.

-

Cosmetic Packaging Molds

Used in the injection molding of cosmetic packaging parts requiring high precision and smooth finishes.

-

General Plastic Injection Molds

Perfect for a variety of plastic molding applications where precision and surface finish are critical.

Mold Structure & Design Description

The Plastic Injection Molding Parts with Polished Surface Treatment are integrated into the mold core system. They are designed to withstand high temperatures, ensuring that the molded parts come out with excellent surface integrity and minimal defects. The parts are designed with custom screw and threaded features, which make them easy to integrate into complex mold structures and ensure a perfect fit during the molding process.

Manufacturing Capability & CNC Machining

-

CNC Milling & Turning

State-of-the-art CNC machines ensure high precision in creating complex mold components.

-

Surface Treatment Expertise

Polishing processes are carefully executed to achieve smooth, uniform finishes necessary for high-performance molds.

-

Advanced Threading Solutions

We provide custom threading services that meet the stringent requirements of our customers, ensuring perfect fit and function in mold assembly.

-

ISO 9001 Quality Management

All products are manufactured under strict quality controls, ensuring consistent performance and reliability.

Custom Development / OEM Cooperation Process

-

Initial Inquiry & Design Review

Customer provides 2D/3D drawings, material selection, and required tolerances.

-

Feasibility Assessment

Our engineers review designs and provide suggestions for optimization where applicable.

-

Production Process

High-precision CNC machining, polishing, and threading are applied based on customer specifications.

-

Inspection & Testing

Dimensional accuracy and surface finish are rigorously inspected to meet the highest standards.

-

Packaging & Delivery

Molding components are securely packaged and shipped worldwide to meet customer deadlines.

Quality Control & Export Experience

-

ISO 9001 Certified

Ensures all processes comply with international standards for quality control and traceability.

-

Advanced Inspection Systems

Precision measuring tools and equipment ensure compliance with the strictest tolerance requirements.

-

Global Shipping and Export

Senlan Precision has experience delivering high-quality components globally, ensuring fast and secure shipments.

Related Products (Internal Links)

-

Plastic Injection Molding Core Pins

-

Customized Mold Inserts

-

Cavity Core Components for Injection Molding

-

High-Precision CNC Machined Mold Parts

FAQ

Q1: Can I get customized threading on the molding parts?

Yes, we offer tailored threading options based on your specific needs.

Q2: What material is used for these parts?

We use high-quality, durable steel materials like S45C, H13, and 1.2344, depending on the required application.

Q3: How do I submit my design?

You can submit your 2D/3D drawings in any common format (such as .dwg, .stp, or .step), and we will review them to ensure manufacturing feasibility.

Q4: What is the typical lead time for custom molded parts?

Lead times vary depending on complexity, but typically range from 2 to 4 weeks after design approval.

Q5: Are inspection reports available?

Yes, detailed inspection reports can be provided upon request to verify dimensional accuracy and quality.

Get a Quote

To receive a custom quote for your Plastic Molding Parts with Polished Surface Treatment and Threaded Inserts, contact Senlan Precision today.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!