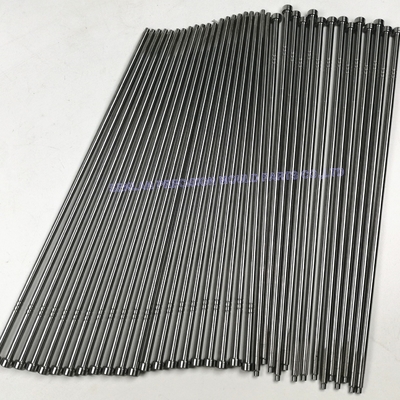

SKH51 Non-Standard Sleeve Ejector Pins and Sleeves

Precision mold components designed for injection molding applications. Ejector pins are critical components that drive into the rear of mold cavities to eject finished pieces, also known as knockout pins.

Key Features

- Multiple diameter options and customizable lengths

- Wide range of tolerance levels available

- Ready-to-install with precision tolerances up to ±0.01mm

- Transparent, user-friendly ordering process

- Direct delivery time and customized pricing display

- Short delivery times

Product Specifications

| Material |

SKH51, Carbide, ASP23, SKD11, SKD61, HSS, A2, M2, D2, SUJ2, S45C, etc. |

| Standard |

Dayton, Lane, DIN, ISO, MISUMI, EDM, FIBRO, MOELLER, HASCO, etc. |

| Size |

Customized according to your drawings or product standards |

| Place of Origin |

Dongguan, Guangdong, China |

| Heat Treatment |

Available |

| Surface Work |

TiCN, TiN, Aitain, Ticrn, nitriding, Black oxygened, Black coating, etc. |

| Tolerance |

±0.005mm |

| Polishness |

Close to Ra0.2 |

Technical Considerations

Working temperature significantly impacts ejector pin lifetime and durability. Using pins designed for low-temperature environments in high-temperature applications will reduce service life. Common ejector pin types include through hard pins, nitride H13 pins, and black ejector pins - each designed for specific operating conditions.

Product Range

We specialize in high-precision mold components including ejector pins, slide retainers, latch locks, date stamps, locating units, ejector series, air poppet valves, and cooling systems. Compatible with HASCO, D-M-E, JIS, CUMSA, PROGRESSIVE, STRACK, SUPERIOR standards. Custom designs available for special requirements.

Our Services

- Customer-focused solutions tailored to your needs

- Quick sample delivery and BOM-based production

- Professional production team with strict quality control

- One-stop solutions for long-term customers

- Custom sizes and OEM/ODM services

- 100% pre-delivery inspection with quality warranty

- Competitive pricing, excellent service, and flexible trade terms

Frequently Asked Questions

Are you a trading company or manufacturer?

We are a manufacturing company specializing in precision mold parts, die casting mold parts, plastic injection mold parts, and machined components.

How do you provide a quote?

Please provide detailed product drawings with the following specifications: materials, surface finish, tolerance requirements, quantity, and technical drawings (3D/CAD/2D). These details are essential for accurate pricing.

How do I track my delivery?

We provide tracking numbers from shipping agents and maintain regular updates on shipping status throughout the delivery process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!