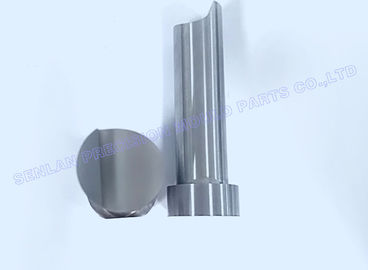

Non-Standard Precision Molded Parts Die Casting Mould Core Pins With Cutting End

For die casting mold parts, we use premium imported steel including 1.2344, 8407, and DAC, offering excellent yield and tensile properties, superior wear resistance, corrosion resistance, and impact resistance. Our unique surface treatment technology significantly extends product lifespan. We utilize world-class testing equipment to ensure strict quality control throughout the manufacturing process.

We prioritize material selection and component durability. Years of machining expertise, high-quality imported materials, advanced imported machining equipment, leading-edge testing instruments, and a comprehensive quality management system guarantee superior product components.

Product Specifications

| Material |

1.2344 |

| Hardness |

48-52 HRC or material dependent |

| Heat Treatment |

Available |

| Service |

Made-to-order |

| Surface Treatment |

TiCN, TiN, Aitain, Ticrn, nitriding, Black oxygened, Black coating, etc. |

| Closest Tolerance |

±0.005mm |

| Polishness |

Ra0.6 |

| Axiality |

0.005mm |

| Verticality |

0.005mm |

Main Products

SENLAN manufactures a comprehensive range of standard and customized ejector pins, punches, insert pins, cavity pins, core pins, mold cores, and other mold accessories and die parts.

Manufacturing Equipment

| Equipment Type |

Brand |

Model |

Precision |

Quantity |

Origin |

| CNC |

TAKISAWA |

NEX-108 |

0.002mm |

4 |

Japan |

| WEDM |

SODICK |

AQ400LS |

0.003mm |

2 |

Japan |

| CHMER |

G435 |

|

0.005mm |

1 |

Taiwan |

| EDM |

CREATOR |

CJ-235 |

0.005mm |

4 |

Taiwan |

| Mirror EDM |

SODICK |

Sodick-AM30LS |

0.003mm |

2 |

Japan |

| MAKIMO |

EDGE2 |

|

0.002mm |

1 |

Japan |

| Desktop lathe |

JINGCHENG |

YB-15 |

0.05mm |

4 |

China |

|

|

YB-25 |

0.05mm |

2 |

|

| OD grinder |

HOTMAN |

FX-03 |

0.002mm |

5 |

China |

| ID grinder |

HOTMAN |

FX-05 |

0.002mm |

3 |

|

| Centeless grinder |

HOTMAN |

FX-12S |

0.001mm |

2 |

China |

| Surface Grinder |

SHUGUANG |

614 |

0.001mm |

4 |

China |

|

|

618 |

0.001mm |

2 |

|

| EDM drilling |

ZENBANG |

ZB-03 |

0.01mm |

1 |

Taiwan |

| Miller |

TOPINR |

AVA |

0.01mm |

2 |

|

Frequently Asked Questions

How can I get the accurate price?

For accurate pricing, please provide 3D drawings in STP, IGS, or X-T format along with your required quantity.

Are you a trading company or manufacturer?

We are a factory.

I have an idea for a new product, but don't know if it can be manufactured. Can you help?

Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and can advise on materials, tooling, and likely set-up costs.

What type of mould tool do I need?

Mould tools can be either single impression (one part at a time) or multi-impression (2, 4, 8 or 16 parts at a time). Single impression tools are generally used for small quantities up to 10,000 parts per year, while multi-impression tools are for larger quantities. We can evaluate your projected annual requirements and recommend the optimal solution.

If I've decided to go ahead with my project, how long will it take to get the trial shot sample?

Tooling manufacturing typically takes 3-8 weeks depending on part complexity and number of impressions (single or multi). After tooling completion, trial shot samples are delivered within 2-3 days.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!