Product Overview

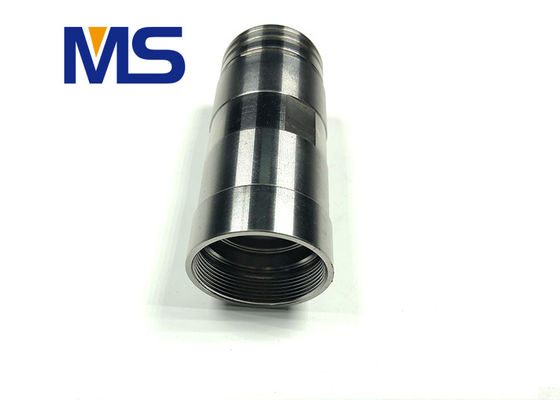

Our Metal Precision CNC Machined Parts are engineered for high-performance applications, providing exceptional accuracy and reliability. These grinding thread small tools, with a maximum diameter of 200mm, are ideal for precision machining in medical device manufacturing, packaging industries, and various mold-making applications. The parts are customizable to meet specific project requirements, and we offer OEM services with Built-to-Print capabilities for precision molding.

Key Features & Advantages

-

Maximum diameter of 200mm for versatile tool sizing

-

Grinding thread technology for precise threading in machining

-

CNC machining ensures high precision and tight tolerances

-

Durable materials selected for strength, resilience, and corrosion resistance

-

Custom-built solutions tailored to your exact requirements

-

OEM and Built-to-Print services available

-

High-quality surface finishes for reliable performance

-

Enhanced tool longevity through advanced grinding technology

-

Suitable for multi-cavity molds and high-precision manufacturing applications

Applications & Industry Usage

Our Metal Precision CNC Machined Parts are suitable for a variety of industries and applications, including:

-

Packaging manufacturers, especially those producing bottle caps, closures, and seals

-

Medical device manufacturers, requiring precise tools for injection molding

-

OEM manufacturers, providing custom machining for multi-cavity molds

-

Engineering companies needing high-precision machined parts for automated systems

-

Injection molders producing parts with high dimensional accuracy

These tools meet the most demanding specifications for high-volume production, ensuring reliable performance and high efficiency.

Mold Structure & Design Description

Our CNC Machined Parts are designed with precision and durability in mind:

-

Threaded grinding provides a clean and precise finish for threaded parts

-

Maximum diameter of 200mm accommodates larger molds and tools

-

CNC machining ensures accurate tolerances (typically within ±0.01mm)

-

Durable materials like tool steel and alloys offer extended tool life under heavy use

-

Surface finishing treatments ensure smooth operation and increased wear resistance

-

Custom thread profiles and grooves are tailored to meet specific project requirements

These features allow for high-precision machining in demanding industrial environments.

Manufacturing & CNC Machining Capabilities

Our state-of-the-art CNC machining facility is equipped to handle both small and large volume orders with high precision and tight tolerances:

-

CNC turning and grinding for smooth and accurate surfaces

-

Advanced grinding technology for precise threading

-

Material expertise in high-strength alloys and tool steels

-

Advanced measuring equipment for quality assurance and dimensional accuracy

-

In-house production and quick turnaround for both prototypes and high-volume orders

-

Low to high-volume machining with consistent quality control

We have the capacity and expertise to produce high-precision components with tailored designs.

Custom Development & OEM Cooperation Process

We provide custom development and OEM services to meet your specific needs, including Built-to-Print solutions. The process involves:

-

Initial consultation to understand project requirements and specifications

-

Design and engineering analysis to ensure feasibility and precision

-

Prototyping for testing and approval

-

CNC machining with custom thread grinding and surface finishing

-

Inspection and final quality check to ensure dimensional accuracy

-

Fast shipping for on-time delivery and global shipping options

We work closely with our clients to ensure that every part meets the highest standards and performs as required.

Quality Control & Export Experience

We maintain rigorous quality control processes to ensure that each part meets the required industry standards:

-

Material selection and certification for durability and strength

-

In-process inspections to ensure precision and fit

-

Final quality checks to verify tolerances, surface finishes, and functional performance

-

Shipping and export capabilities for global clients with timely delivery

With extensive export experience, we can support international shipping and ensure safe delivery of your orders.

Related Products (Internal Links)

-

CNC Precision Machining for Medical Devices

-

Injection Mold Components

-

Custom CNC Parts for Packaging

-

High-Precision Mold Inserts

-

OEM Custom CNC Machining Services

Frequently Asked Questions (FAQ)

Q1: Can I customize the thread design on these parts?

Yes, we offer custom thread profiles and groove designs tailored to your exact specifications.

Q2: What is the maximum size you can machine for these parts?

We can machine parts up to 200mm in diameter, ideal for large molds and high-performance tools.

Q3: What materials do you use for CNC machining?

We offer a range of high-strength materials, including tool steels and alloy steels, to ensure durability and long-lasting performance.

Q4: How do I place an order for custom CNC machined parts?

Please share your drawings or specifications, and we will provide a technical evaluation and quotation based on your requirements.

Q5: Do you offer international shipping for custom CNC parts?

Yes, we provide global shipping and can support international mold assembly.

Request a Quote

Please provide your drawings or project specifications to receive a detailed quote for CNC machined parts with custom thread grinding and surface finishing.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!