Custom Precision Mold Components | $pm$0.005mm Core Pins, Inserts & Cavity Liners

Product Overview

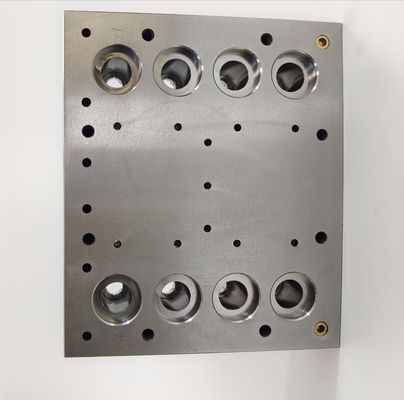

Senlan Precision manufactures precision custom mold parts, including mold inserts, mold cores, core components, and line-A pieces for plastic injection molds. All components are produced strictly according to customer drawings and technical specifications, focusing on dimensional accuracy, interchangeability, and long-term mold stability in high-cycle production environments.

Key Features & Technical Advantages

-

Built-to-Print manufacturing based on customer drawings or CAD data

-

Suitable for mold inserts, mold cores, core pins, and line-A mold components

-

Stable dimensional control for tight tolerance mold assemblies

-

Consistent surface finish for reliable molding performance

-

Designed for easy replacement and mold maintenance

-

Compatible with single-cavity and multi-cavity injection mold systems

Applications & Industry Use

Precision custom mold parts from Senlan Precision are widely applied in:

-

Bottle and packaging injection molds

-

Cap, closure, and dispensing system molds

-

Medical disposable and syringe mold tooling

-

Laboratory and healthcare plastic component molds

-

High-output packaging mold systems

These components are used exclusively as industrial mold tooling parts, not finished consumer products.

Mold Structure & Design Description

Custom mold parts such as inserts, cores, and line-A pieces function as critical forming and alignment elements within injection molds. Design considerations typically include:

-

Accurate mating surfaces to ensure cavity alignment

-

Controlled clearances for consistent plastic flow and part quality

-

Structural stability under high injection pressure

-

Modular design for quick replacement and reduced downtime

Senlan Precision manufactures strictly according to approved designs without design modification unless requested.

Manufacturing Capability & CNC Machining

Senlan Precision operates advanced precision machining systems, including MAKINO (Japan) and HARDINGE (USA) CNC equipment, ensuring repeatable accuracy and process stability.

Manufacturing capabilities include:

-

High-precision CNC milling and turning

-

EDM machining for complex internal geometries

-

Surface grinding and controlled polishing

-

Heat treatment coordination per material requirements

-

In-process and final dimensional inspection

All machining processes are executed to meet drawing-defined tolerances.

Custom Development & OEM Cooperation Process

Our standard OEM / Built-to-Print workflow includes:

-

Technical drawing and specification review

-

Manufacturing feasibility evaluation

-

Precision machining and controlled processing

-

Dimensional inspection and quality verification

-

Packaging and export delivery

We support both prototype quantities and long-term production supply.

Quality Control & Export Experience

Quality control is integrated throughout the production process:

-

Incoming material verification

-

In-process dimensional checks

-

Final inspection prior to shipment

-

Optional inspection reports upon request

With extensive export experience, Senlan Precision supports international customers with stable communication, documentation, and delivery control.

Related Products

-

Mold core pins and cavity inserts

-

Multi-cavity mold components

-

Precision sleeves, bushings, and wear parts

-

Customized mold spare parts for packaging and medical molds

All related products are available on a customized / OEM / Built-to-Print basis.

Technical FAQ

Q1: Do you offer standard mold parts?

No. All mold parts are manufactured according to customer drawings.

Q2: Can you produce replacement parts for existing molds?

Yes. Replacement inserts and cores can be produced to match existing molds.

Q3: Are multi-cavity molds supported?

Yes. Our mold parts are suitable for high-cavity injection mold systems.

Q4: Do you provide design services?

We manufacture strictly according to approved drawings unless design support is specifically requested.

Request a Quotation

For precision custom mold parts, mold inserts, mold cores, or line-A pieces, please provide your drawings and technical requirements.

Our engineering team will review your project and provide a detailed quotation with lead time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!