Custom Precision Injection Molding Service | High-Quality Mold Making & Plastic Parts

Product Overview

Senlan Precision provides custom molding services focused on precision injection molding molds and plastic injection mold parts. We specialize in built-to-print mold manufacturing, supporting multi-cavity molds, high-precision mold components, and customized tooling solutions for packaging, medical, and industrial plastic applications. All molds and components are engineered strictly according to customer drawings and technical specifications.

Key Features & Technical Advantages

-

Custom injection mold design and manufacturing

-

Built-to-Print / OEM mold and mold component production

-

Support for single-cavity and multi-cavity mold structures

-

High dimensional accuracy and stable mold performance

-

Integrated manufacturing of mold cores, cavities, and inserts

-

Suitable for high-volume and high-cycle production molds

-

Engineering-driven process, not standardized off-the-shelf molds

Applications & Industry Use

Our custom molding services are widely applied in:

-

Bottle and packaging product molds

-

Cap, closure, and sealing component molds

-

Medical consumables and laboratory plastic molds

-

Industrial plastic component molds

-

Precision plastic parts requiring tight tolerance control

We focus on tooling and mold manufacturing rather than finished consumer products.

Mold Structure & Design Description

Injection molds manufactured by Senlan Precision are developed based on customer-provided drawings or confirmed designs. Typical mold structures include:

-

Mold cavity and core inserts

-

Multi-cavity layouts for productivity optimization

-

Ejection systems designed for part stability

-

Cooling channel layout optimized for cycle time control

-

Replaceable wear components for extended mold life

Design validation is performed to ensure manufacturability and long-term mold stability.

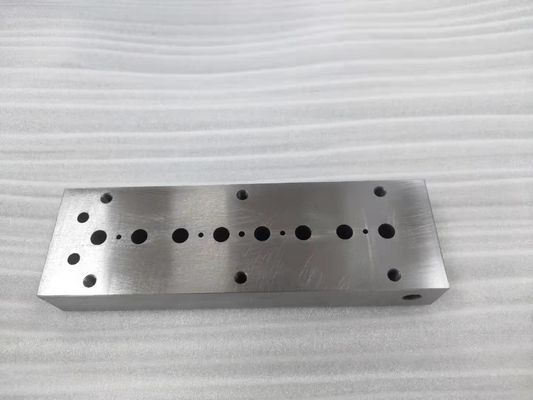

Manufacturing Capability & CNC Machining

Senlan Precision is equipped with advanced machining and finishing equipment, including MAKINO (Japan) and HARDINGE (USA) precision machines.

Our manufacturing capabilities include:

-

Precision CNC milling and turning

-

High-accuracy EDM machining

-

Surface grinding and fine polishing

-

Heat treatment and stress relief

-

Full-process dimensional control for mold components

All processes are controlled to meet drawing-defined tolerances.

Custom Development & OEM Cooperation Process

We follow a structured Built-to-Print OEM workflow:

-

Drawing review and technical feasibility evaluation

-

Mold structure and process planning

-

Precision machining and component manufacturing

-

Assembly, inspection, and validation

-

Packaging and export delivery

We support prototype molds, production molds, and long-term spare part supply.

Quality Control & Export Experience

Senlan Precision maintains strict quality control standards for mold manufacturing:

-

Incoming material inspection

-

In-process dimensional checks

-

Final inspection before shipment

-

Traceable documentation upon request

With extensive export experience, we ensure reliable communication and stable delivery for international customers.

Related Products

-

Injection mold core and cavity inserts

-

Precision mold pins and sleeves

-

Multi-cavity cap and closure molds

-

Customized plastic injection mold components

All related products are available on a customized / OEM / Built-to-Print basis.

Technical FAQ

Q1: Do you offer standard molds?

No. All molds and mold parts are custom-manufactured based on customer drawings.

Q2: Can you manufacture mold components separately?

Yes. We supply complete molds as well as individual mold parts and inserts.

Q3: Are multi-cavity molds supported?

Yes. We specialize in multi-cavity mold structures for packaging and medical applications.

Q4: Do you provide injection molding production?

Our core service focuses on mold and mold component manufacturing. Injection molding production support can be discussed case by case.

Request a Quotation

For inquiries regarding custom injection molding molds or plastic injection mold parts, please provide your drawings or technical specifications.

Our engineering team will review your requirements and provide a detailed quotation and lead time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!